Pouring a Concrete Slab in Norwalk: Cost & Timeline

Concrete Slab Norwalk

To successfully install a concrete slab in Norwalk, it is important for homeowners to understand the costs, timelines, and regulations that will affect the successful completion of their project. The cost of installing a concrete slab in California and the premium prices charged by Southern California builders can have an extreme effect on a homeowner’s budget and their ability to schedule the installation of a new concrete slab. Concrete slab installation is a professional process that includes coordinating several factors, such as obtaining all required permits, selecting and ordering the necessary materials, hiring a qualified contractor, and coordinating with local weather forecasts that are specific to the type of Mediterranean climate found in Norwalk. A homeowner’s costs when it comes to installing a concrete slab will be affected by the size of the project, the thickness of the concrete slab that they require, the conditions of the site where the slab will be poured, and the specifications for the finish work of the slab, which will determine how well the slab will perform over time. If a homeowner has a good understanding of a complete project timeline, then they will be able to plan and make educated decisions regarding the installation of their new concrete slab, while ensuring that the quality of the installation meets or exceeds local building code requirements and will provide them with many years of reliable service.

2026 Residential Slab Installation Cost Breakdowns in Norwalk

Concrete foundation pricing in Norwalk is generally between $9–$16 per square foot for a residential installation, which reflects higher California-based material and labor costs. Residential, four-inch-thick slabs are generally priced at about $9–$12 per square foot, while six-inch-thick residential slabs for driveway use or heavier applications will be priced at about $12–$16 per square foot installed.

- A general estimate of a 600-square-foot, 20 x 30-foot garage slab would be in the range of $5,400 to $9,600 based upon the thickness of the slab, the type of reinforcement used, and site preparation requirements.

- Smaller patio installations of 12 x 16 feet (192 square feet) would be priced at about $1,700 to $3,000 installed.

- Premium options such as decorative finishes, colored concrete, or special reinforcement types will increase the price of each square foot of slab installation anywhere from $2 to $8 per square foot across the Greater Los Angeles Area.

Factors Which Affect Total Project Pricing

Site preparation has a significant impact on the total cost of all projects, especially in established residential areas, since the physical constraints imposed by other structures or site access may limit the ability of installers to perform their work efficiently. Therefore, site preparation costs can vary greatly depending on soil conditions, the depth of the excavation, etc., with costs ranging from $1 to $3 per square foot. In addition, some residential areas have unique circumstances due to proximity to major transportation routes or large parks (e.g., Pioneer Boulevard, Holifield Park), which may also create additional utility clearance or drainage modification requirements.

Reinforcement requirements can also have a substantial impact on both the material and labor costs associated with installing residential concrete slabs. Wire-mesh reinforcement, for example, may add up to $0.20 to $0.30 per square foot, while using rebar reinforcement can increase costs by $2 to $3 per square foot. In addition to reinforcement, residential concrete installations frequently involve the inclusion of vapor barriers, expansion joints, and properly prepared bases, all of which contribute to the total cost of the project. As a result, high-quality concrete contractor services offer a comprehensive package of installation services that includes all of the necessary components for a successful and durable installation.

Components of Material and Labor Costs

The cost of ready-mix concrete in the Los Angeles Area averages out to about $166 to $190 per cubic yard when delivered, with premium mixes having a higher price point to enhance durability. The cost of labor represents approximately 40–50% of total project costs, with an average price of about $3 to $5 per square foot for a professional installation that includes forming, placing, finishing, and cleanup services.

In addition to the cost of materials and labor, other costs, such as the cost of forms, reinforcement, tools, and finishing materials, can add another $1 to $2 per square foot to the total cost of basic concrete. As a result, high-quality contractors manage the entire slab installation process and provide coordination for material deliveries, scheduling of crews, and scheduling of completion to maximize project efficiency and minimize weather-related delays.

Timeline and Scheduling of Project Completion

The general time frame to complete a slab installation is between 3 and 5 days, depending on the size and complexity of the project. The first day of the project is spent preparing the site for the installation, excavating the site, and laying down the base material. The second day of the project is spent setting up the forms, placing the reinforcement into position, and making final preparations for the delivery of the concrete. On the third day of the project, the concrete is placed, the initial finishing is performed, and the surface texture work is completed.

Although the curing requirements for concrete extend the project timeline far beyond the initial placement. After being placed, concrete will reach sufficient strength to allow foot traffic within 24–48 hours; however, it will take 7 days to reach approximately 70% of its final strength. However, it will take 28–30 days to reach full design strength, although normal use of the concrete can begin after one week with proper precautions.

Requirements and Compliance for Permits

Before the installation of most concrete slabs in Norwalk, the City of Norwalk’s Building and Safety Department requires a building permit for almost all installations, especially those larger than 120 square feet or those involving structural elements. It normally takes the City of Norwalk’s Building and Safety Department 1–2 weeks to process permits for concrete slab installations, depending on the complexity of the project and the workload of the department at the time. Plans submitted with permit applications must show details of dimensions, reinforcement, and drainage.

The cost of permits can range from $150 to $500, depending on the scope and value of the project. Although high-quality contractors will assist homeowners in obtaining permits and coordinating the necessary inspections, homeowners can expect to pay for the permit themselves. Prior to the installation of the concrete, there will be a footing inspection to determine if the footing meets city codes and regulations. There will be a final inspection after the completion of the installation to verify that the installation was done in accordance with city codes and regulations.

Seasonal Scheduling Considerations

Since Southern California’s climate allows for the installation of concrete year-round, there are many factors that can influence the scheduling of a project and the cost of the project. One factor is the need to manage temperature extremes to prevent premature curing and damage to the finished surface of the concrete. To accomplish this, contractors prefer to pour concrete in the early morning so that they do not have to contend with extreme temperatures during the hottest part of the day.

On the other hand, there are benefits to performing installations in the winter months. These benefits include better curing conditions and possibly less competition for contractor services. However, it is always possible that rain may cause delays in completing an installation, and, therefore, it is important for homeowners to make sure that the contractor they hire monitors the weather forecast regularly and makes provisions for protecting the freshly poured concrete from the elements.

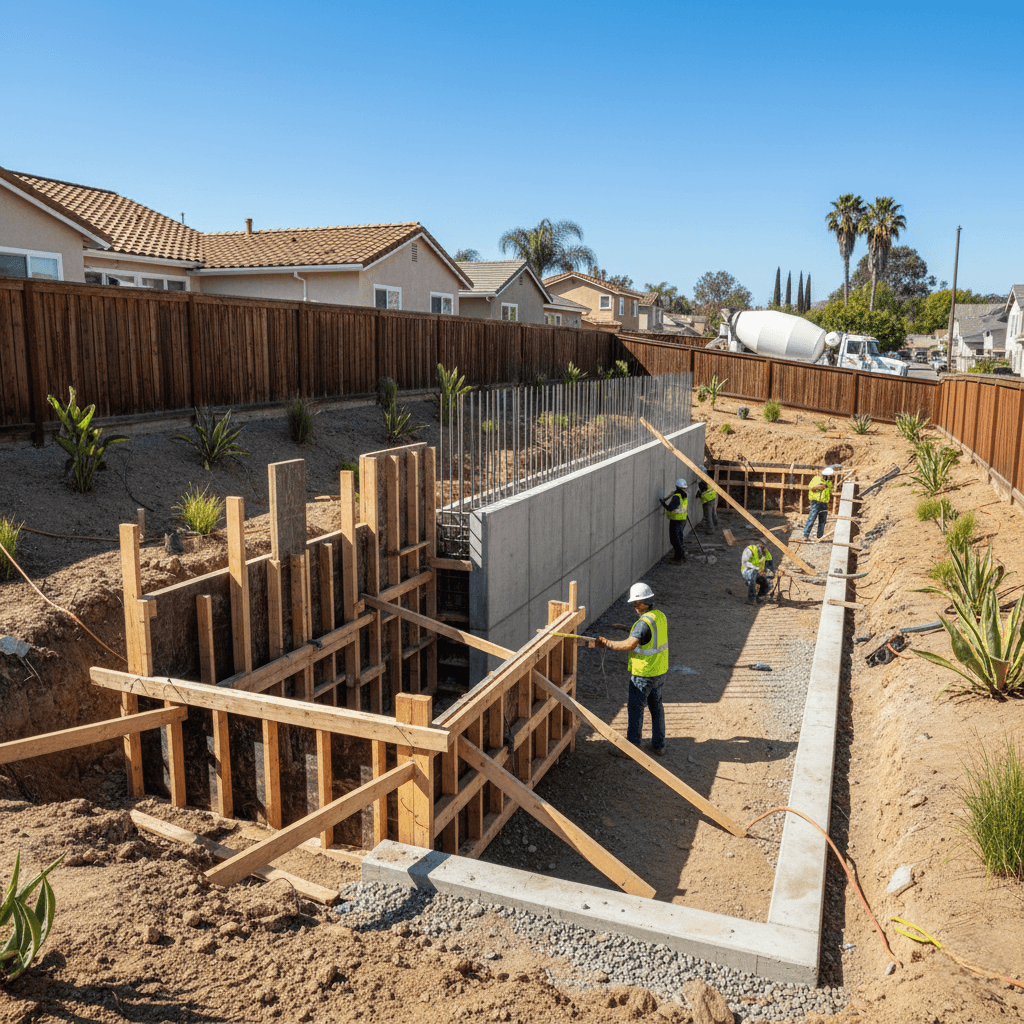

Site Preparation and Access Requirements

Ensuring that the site is properly prepared for a concrete installation is critical to achieving long-term performance of the slab and avoiding costly repairs in the future. Before any excavation is performed, a soil analysis should be conducted to determine the appropriate base-course requirements and to identify any potential issues, such as expansive clays or inadequate drainage. Due to the physical constraints created by other structures in established residential areas, the access available to the installer can be limited, and, therefore, the equipment and methods used to deliver the concrete and place it can be severely restricted. Therefore, in some cases, concrete pumping may be necessary to place the concrete in difficult-to-access locations, and this will increase the cost of the concrete by $2 to $4 per cubic yard.

Quality Control and Inspection Process

High-quality installations of residential concrete slabs involve a number of quality control checks throughout the installation process. These quality control checks include pre-pour inspections to ensure that the site is properly prepared, the forms are aligned correctly, and the reinforcement is in the correct location. Once the concrete is placed, the contractor monitors the temperature of the concrete, the consistency of the concrete, and the amount of time allowed to pass prior to the first finishing operation to ensure optimal results.

After the installation is complete, the contractor performs a series of quality control inspections to check the quality of the surface of the concrete, the quality of the curing process, and the accuracy of the dimensions of the slab. High-quality contractors also document the design of the concrete mix, the test results of the concrete, and the procedures used to install the concrete to support warranty claims. Quality control prevents common problems such as cracking, settling, or surface deterioration of the slab, which can reduce the longevity of the slab and the value of the property.

Long-Term Value and Maintenance

Well-installed residential concrete slabs provide excellent value through the years because they can last for decades without needing much maintenance. Properly installed slabs, with the right type and amount of reinforcement, will prevent many common problems such as cracking, settling, and surface deterioration. Therefore, spending money on good-quality materials and hiring a qualified contractor to install the slab will ultimately save you money over the years through less frequent repairs and increased value of your home.

Regular maintenance of the slab consists of periodically cleaning the surface of the slab, filling small cracks, and applying protective coatings to the slab every 3–5 years. Many high-quality contractors will also provide maintenance programs to keep the appearance of the slab looking great and maintain the structural integrity of the slab throughout its lifespan. In addition, providing a comprehensive warranty for the installation of the slab demonstrates a level of confidence by the contractor that the installation was done correctly and gives the homeowner peace of mind.

Professional Concrete Slab Installation Services

At Norwalk Concrete Works, we manage all aspects of the installation of a residential concrete slab in Norwalk and surrounding communities, from getting the permits to the final inspection. We are confident that our skilled team will install a quality slab on time and within budget, which will provide you with many years of service and value.