How to Protect Resurfaced Concrete in Norwalk Homes

Concrete Resurfacing Norwalk

To provide the best possible protection for resurfaced concrete in Southern California’s environment of extreme UV, temperature swings, and low rainfall, a well-planned maintenance program is required. As a homeowner in Norwalk, you will have to consider these climate-specific demands when planning for the future of your resurfaced concrete as it relates to sealing, scheduling maintenance programs, and the impact of the environment on the longevity of your newly resurfaced concrete surface. Regular and quality maintenance of your resurfaced concrete will extend its lifespan, protect its appearance, and maintain its structural integrity through all four seasons, thus protecting against expensive repairs and providing the greatest return on investment from your concrete resurfacing project.

Understanding California Climate Impacts

The Southern California environment, due to its Mediterranean climate, creates a number of challenges for resurfaced concrete surfaces. The most important are extreme UV exposure and large day-to-day temperature fluctuations. As concrete expands and contracts daily with morning lows and afternoon highs, the overlay material is subjected to continuous stress. UV rays degrade unprotected surfaces as well by causing color loss, surface chalk, and earlier deterioration of protective coating systems.

In addition to the extreme temperatures, the desert conditions of Norwalk, including extremely low humidity, result in very fast moisture evaporation rates, which can negatively affect both curing processes and the stability of the surface. Seasonal Santa Ana winds bring dust and debris that will eventually abrade the unprotected surfaces. Projects involving resurfacing concrete in Norwalk, therefore, need to consider the climate of the area in order to achieve the longest possible life of the newly installed surfaces.

Important Sealers and Protective Coatings

Sealers of the highest quality represent the first line of defense against the negative effects of the environment and surface degradation. For the extreme climate of Southern California, penetrating sealers are the best type of sealer. Penetrating sealers are different from film-forming sealers because they do not leave a film on the surface that can blister or peel off when exposed to the sun. In addition, penetrating sealers allow the surface to breathe by allowing moisture vapor to escape while preventing water, stains, and contaminants from entering the surface.

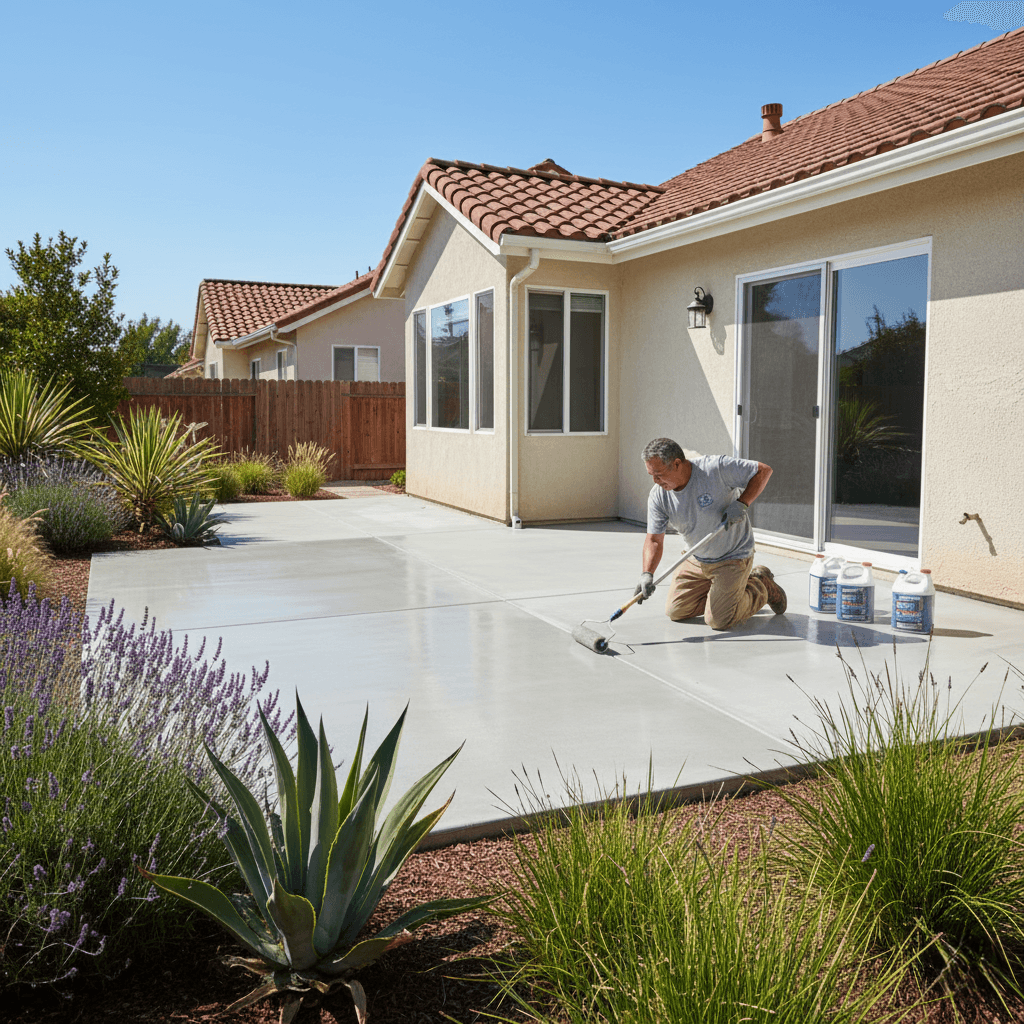

Acrylic sealers that contain UV-resistant additives have an exceptional ability to protect against sunlight damage while also improving the surface color retention and appearance. Sealers must be applied when the ambient temperature is between 50 and 90 degrees F for the best possible penetration and curing. Protecting a coated surface involves applying multiple thin coats of the product, rather than one thick coat, to provide uniform coverage and maximize the durability of the coating throughout all possible climate conditions.

Creating Maintenance Schedules

Create comprehensive maintenance schedules that take into consideration the climate of the local area and the level of surface exposure. Conduct monthly visual inspections to detect any potential problems before they become major issues that may require expensive repair or total resurfacing. Clean the surface of dirt, dust, and organic debris that may stain or damage protective coatings every quarter by using mild detergent and low-pressure water.

Clean and apply additional coats of protective sealer to the surface annually to maintain maximum protective levels in the challenging climate conditions of Norwalk. Major maintenance should be scheduled during the cooler months of the year when temperature and humidity conditions are ideal for applying and curing protective coatings. Document all maintenance treatments, observations, and evaluations for future reference in your resurfacing maintenance guides.

Cleaning and Care of Resurfaced Concrete Surfaces

Regular cleaning of the surface helps to prevent the accumulation of debris that can trap moisture and promote the deterioration of the surface. Cleaning of the surface can be done by using soft-bristled brooms for sweeping; however, it is recommended to avoid using steel brushes or aggressively scrubbing the surface, as this may damage the protective coatings. Spills should be addressed promptly to prevent staining and chemical damage to the underlying overlay materials.

When pressure washing surfaces, the pressure setting should be kept in the moderate range (1500-2500 psi) and use a wide fan nozzle to avoid damaging the surface texture or protective systems. Unless preparing the surface for a maintenance coating application, high-temperature pressure washing should be avoided. Contractors often give recommendations regarding gentle cleaning methods to maintain protective coatings while keeping the surface clean.

Protection Strategies by Season

Summer protection includes protecting surfaces from UV damage and thermal shock. Reflective coatings or light colored sealers should be applied to surfaces to minimize heat absorption and surface temperature extremes. Adequate drainage should be ensured around surfaces to prevent water from collecting during rare summer thunderstorms.

Winter preparation includes inspecting and repairing cracks or damaged coating systems before the start of the wet season. Although Norwalk typically does not experience freezing temperatures, cold temperatures combined with moisture can cause expansion issues in compromised surfaces. Protective concrete finishes should be flexible enough to move with the surface during the seasons without cracking or delaminating.

Managing Traffic and Use

Limit traffic patterns on newly resurfaced concrete for a minimum of 30 days after installation to allow for complete curing and adhesion of the coating. Install protective mats or runners during construction activities or events that could potentially damage surfaces. Educate family members regarding proper care procedures and how their actions may damage surfaces.

Placement of furniture should include protective pads to prevent scratching or indentations of decorative surfaces. Dragging heavy objects across resurfaced surfaces should be avoided, and dollies or protective materials should be used when moving equipment. Proper traffic management can extend the life of surfaces significantly while maintaining aesthetic appeal during peak usage periods.

Protecting Chemicals and the Environment

Protect resurfaced surfaces from automotive fluids, fertilizers, and household chemicals that can stain or damage protective coatings. Absorbent materials should be used to quickly address spills and neutralize acidic substances with appropriate cleaning agents. Immediate action should be taken to address pool chemicals, pet waste, and garden runoff to prevent permanent damage to the surface.

Install proper drainage systems to direct water away from resurfaced surfaces to prevent water from accumulating and compromising coating adhesion or causing efflorescence issues. Consider modifying landscaped areas to minimize leaf debris, tree sap, or other organic materials that can stain surfaces. All potential contaminant sources should be addressed systematically in developing concrete weatherproofing strategies.

Early Warning Signs and Action

Regularly monitor surfaces for signs of color change, texture change, or coating wear that indicate maintenance requirements. Hairline cracks, surface chalking, or increased water absorption indicate protective system deterioration that requires immediate attention. Minor issues should be addressed immediately to prevent costly repairs or resurfacing.

Annual evaluation by experienced contractors can identify early warning signs of potential issues that homeowners may not recognize. Contractors can assess coating performance, surface condition, and environmental stressors that can impact the long-term durability of the surface. Addressing minor maintenance issues early can help prevent major repair or replacement costs.

Services for Maintenance

Contractor-provided maintenance services provide the technical knowledge and equipment necessary to properly care for surfaces. Contractors knowledgeable about the climate of Southern California can recommend suitable products and schedules for specific types of surfaces and exposure conditions. Contractors have access to professional-grade equipment and materials not available to homeowners.

Annual evaluations by contractors will assist in optimizing the maintenance approach and identifying potential opportunities for improvement in protective systems. Contractors offering maintenance programs provide consistent care and extend the warranty and performance guarantee of the protective coating systems. Contractor-provided services provide peace of mind and will help to maintain property values through proper care of the surface.

About Norwalk Concrete Works

At Norwalk Concrete Works, we provide overall protection strategies for resurfaced concrete surfaces throughout Norwalk and surrounding communities. Our maintenance programs include annual inspections, professional cleaning services, and protective coating applications designed to meet the extreme climate conditions of Southern California, thus maximizing the performance and longevity of your resurfacing investment for many years to come.