Step-by-Step: How We Approach Concrete Repair in Norwalk

Concrete Repair Norwalk

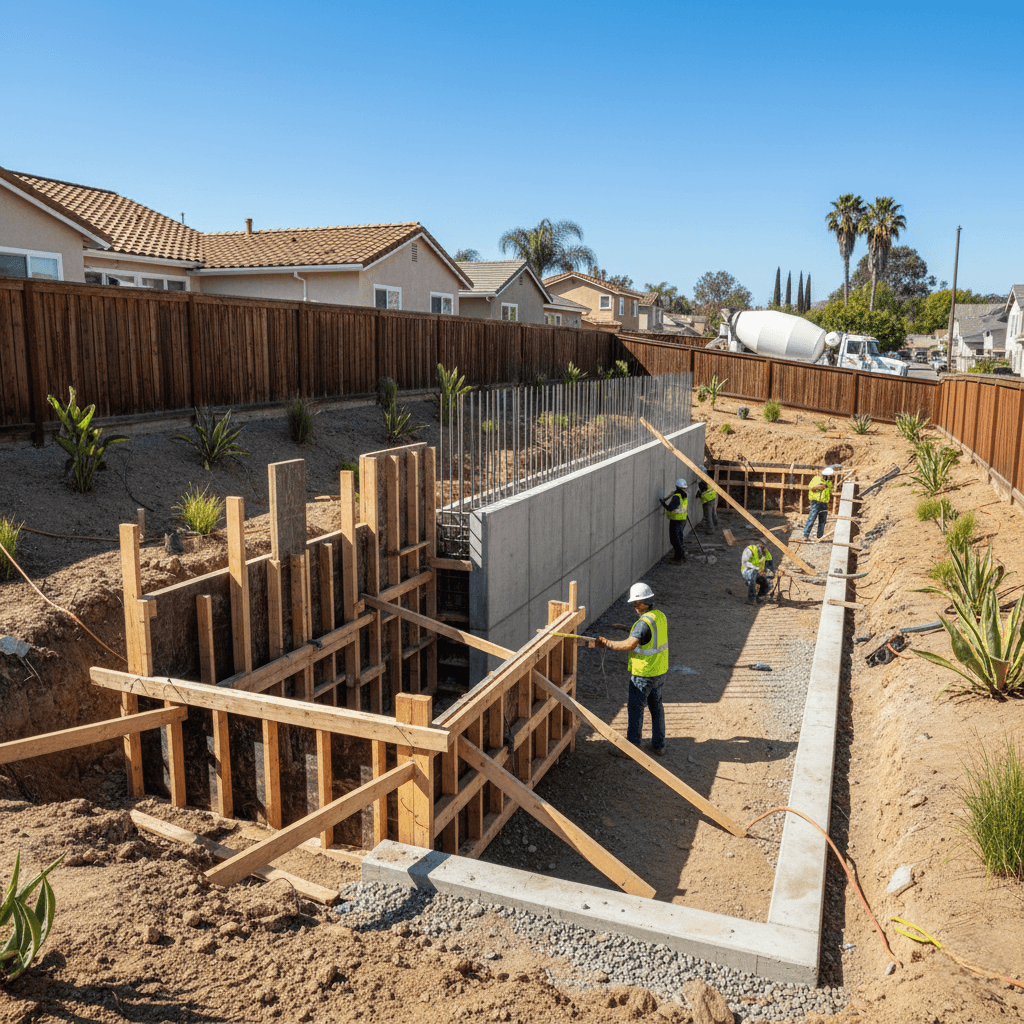

To provide our Norwalk customers with a complete solution to their damaged concrete issues, we have a formalized system of concrete repair, which includes a full assessment and a full plan to execute that assessment to ensure a final product that will last for years to come. Assessment of a customer’s damaged concrete begins with a full written record of how the concrete is currently damaged, as well as a written analysis of why the concrete was damaged, and what type of corrective action should be taken to repair it. Each damaged concrete assessment takes into account regional influences on the repaired concrete, such as seismic activity, types of soils, and local environmental elements that can negatively impact the longevity of a repaired piece of concrete. The repair planning portion of our assessment process will include: an interpretation of the California Building Code, all required permits and local ordinances, and all of the best practices that have been accumulated over decades of experience doing business in the Los Angeles Area. This “step-by-step” approach allows us to ensure that each of our concrete repairs meets the highest possible standards of workmanship and durability for both residential and commercial properties throughout Norwalk.

Step 1: Initial Assessment and Documenting Damage

The first step in our assessment process is to visually inspect all concrete surfaces and document every detail of the damage, including crack patterns, surface deterioration, and structural issues. The assessment process includes taking photographs of the damaged areas and referencing them with measurement markings to track the progress of the repair throughout the entire process. Surrounding conditions such as drainage patterns, soil settlement indicators, and environmental influences are also considered during this initial assessment process.

A complete assessment of the damage will include an evaluation of the underlying cause of the damage, including a structural load analysis and an assessment of the foundation stability. Our staff evaluates the surrounding conditions and utilizes a variety of specialized equipment, including concrete scanners, moisture meters, and strength testing apparatus, to collect a large amount of data. The data collected through the evaluation process serves as the basis for all of the subsequent repair planning and ensures that the correct repair strategy is implemented for each individual project.

Step 2: Identifying Causes of Problems and Evaluating Them

Identifying the root cause of the problem and evaluating it allows us to create targeted repair solutions and avoid future problems. In Norwalk, common issues related to concrete damage include soil movement caused by seasonal changes in moisture content, seismic settling, and age-related deterioration that require different types of repairs. When we assess these issues, we take into consideration the history of how the structure was constructed, environmental exposures, and how the property has been utilized since it was built.

When performing structural concrete repairs, we evaluate load distribution, the condition of the reinforcing steel, and potential safety hazards before commencing work. Soil conditions, the adequacy of the drainage system, and outside influences such as tree roots or utility installations that could be causing continuing damage are also evaluated. By completing this type of assessment, we can develop precise repair specifications and minimize the likelihood of future damage by developing a comprehensive solution to each problem.

Step 3: Developing a Comprehensive Repair Plan and Design

In addition to evaluating the damage and identifying the root cause of the damage, we also develop a comprehensive plan for repairing the damage. This plan includes the selection of materials and the method in which they will be applied, as well as the timeline in which the repairs will be completed and the resources needed to complete the repairs. We consider local climate conditions, access limitations, and building code compliance when creating the repair plan.

The repair plan addresses both the immediate need to repair the damage and the need to develop long-term preventative strategies. When creating the repair plan, we also identify the permits that will be required to complete the repairs and schedule inspections. Additionally, if other trade contractors will be involved in the repair process, we coordinate their involvement in the repair plan.

The selection of materials for the repair is based upon compatibility with the existing concrete, availability of the materials locally, and the performance of the materials under the environmental conditions of Norwalk. The development of a comprehensive repair plan and design ensures that the repairs are properly planned to anticipate any challenges that may arise and to develop a solution to those challenges.

Step 4: Preparing the Surface for Repairs and Removing Contaminants

Preparing the surface for repairs involves removing any loose materials, contaminants, and deteriorated concrete. We utilize a variety of mechanical methods to prepare the surface for repairs, including chipping, grinding, and pressure washing to obtain the desired surface profile. Once the surface has been prepared, all debris, dust, and loose particles are thoroughly removed before applying the repair material.

Preparation of the surface for repairs includes cleaning of the reinforcement steel, removal of corrosion products, and application of protective coatings where required. We prepare the surface to be repaired so that there is sufficient surface roughness for mechanical bonding and to preserve the structural integrity of the adjacent concrete. A properly prepared surface will eliminate the possibility of delamination and ensure that the repair material adheres properly and will last longer.

Step 5: Assessing and Protecting Exposed Reinforcement Steel

Exposure of reinforcement steel necessitates a thorough evaluation of the reinforcement steel, including an assessment of corrosion, a determination of its ability to structurally support loads, and an application of a protective coating to protect the reinforcement steel from further corrosion. When necessary, we clean exposed reinforcement steel to bright metal and apply a corrosion inhibitor or protective coating to the steel. If structural analysis determines that additional reinforcement steel is required to support loads, we install new reinforcement steel as part of the repair process.

We take steps to protect the reinforcement steel from further corrosion to ensure the long-term structural integrity of the concrete. To do so, we select concrete cover depths, bar spacings, and develop lengths that ensure structural integrity. When additional reinforcement steel is installed as part of the repair process, we coordinate with structural engineers to ensure that the modification does not compromise the load-carrying capacity of the structure.

Step 6: Selecting Materials and Following Manufacturer’s Mixing Procedures

Selecting the right materials for the repair is important because the selected materials should be compatible with the existing concrete, have the appropriate physical properties to withstand the environmental conditions of Norwalk, and perform according to the needs of the structure. The type of materials selected will depend on the type of repair being performed and the desired performance of the repair. To ensure that the selected materials meet all of the desired criteria, we specify materials based on the time to set, the development of strength, the degree of shrinkage, and the compatibility with the substrate concrete.

To ensure that the mixed materials have the same properties as the finished product, we strictly adhere to the manufacturer’s instructions regarding mixing proportions, mixing time, and consistency. We monitor the batch proportions, mixing time, and consistency of the mixture to ensure that the repair material meets the specifications of the manufacturer and provides uniform quality throughout the repair process. We also handle the materials properly to prevent contamination and ensure that the properties of the repair material remain consistent throughout the repair process.

Step 7: Applying and Placing Materials Professionally

Applying and placing the repair materials professionally is a critical aspect of the repair process. Skilled application and placement of the materials is necessary to ensure that the repair materials are properly consolidated, bond uniformly with the adjacent concrete, and possess the desired uniform density within the repair area. We utilize the proper tools and methods to apply and place the repair materials, and ensure that the materials are applied and placed at the correct time to optimize the desired performance characteristics of the repair materials.

We understand the importance of timing and the influence of ambient conditions (i.e., temperature, humidity, and wind) on the performance characteristics of the repair materials and the cure of the repair materials. Therefore, we coordinate the application and placement of the repair materials with local weather forecasts and adjust the timing and methods of application and placement as necessary to ensure that the repair materials perform as intended. Our skilled craftsmen are knowledgeable about the various application techniques and finishing techniques for the wide range of repair materials available today.

Step 8: Implementing Curing and Protective Measures

Implementing a systematic curing process is essential to ensure that the repair materials develop the desired level of strength and durability. We develop a curing process that maintains the optimal levels of moisture and temperature to allow the repair materials to develop the desired properties. We select curing processes (e.g., moist curing, membrane curing, steam curing) based on the requirements of the repair materials and the site conditions.

Protective measures are taken to prevent damage to the newly repaired area from weather, pedestrian and vehicular traffic, and construction activities during the critical curing period. The curing process and protective measures must be extended as necessary to accommodate site-specific conditions.

Step 9: Conducting Quality Control and Inspections

Quality control for the repair process includes visual inspection of the repair area and verification of the repair specifications compliance throughout the installation process. We document all aspects of the repair process, including the procedures utilized, materials applied, and environmental conditions affecting the quality of the repairs. Regular inspections are conducted to verify that the repairs comply with the approved plans and specifications.

Following completion of the repairs, a final evaluation of the repair quality and performance verification is conducted. We provide documentation to the building official(s) for required inspections to verify compliance with applicable building codes. Through regular inspections and quality control evaluations, we ensure that the repairs meet the professional standards and client expectations.

Step 10: Performing a Final Evaluation and Establishing Ongoing Monitoring Protocols

Completion of the project includes conducting a final evaluation of the quality of the repairs and verifying the performance of the repairs. We provide the client with a detailed report of the repairs, including materials applied, procedures utilized, and recommendations for ongoing maintenance. Providing education to the client concerning proper care and early detection of potential future problems is also included in the final evaluation process.

Recommendations for establishing monitoring protocols for the repairs are provided to the client, including recommended inspection frequencies, maintenance procedures, and warning signs for potential problems. Warranty information is also provided to the client, along with maintenance guidelines and ongoing support for the repair performance.

This comprehensive approach to assessing damage, planning repairs, and providing ongoing support to clients ensures that they receive maximum value and satisfaction from their investment in concrete repair.

Local Experience and Compliance with Regulations

As a company operating in Norwalk, we have extensive knowledge of the local building codes, permitting requirements, and inspection procedures to facilitate smooth project completion. We understand the soil conditions throughout the area, from residential properties located near the San Gabriel River to commercial properties and schools located near Holifield Park and Pioneer Boulevard. Our local experience enables efficient processing of municipal permits and approvals, and the implementation of repair strategies specifically designed to address regional conditions.

Compliance with regulations includes obtaining the proper permits, coordinating inspections, and providing documentation demonstrating compliance with California building codes. We continually update our knowledge of applicable building codes, industry best practices, and emerging technologies to enhance the effectiveness of our repair strategies. By doing so, we ensure that all projects are completed in accordance with the laws and regulations governing the construction industry.

By combining our experience and expertise with modern techniques and materials, Norwalk Concrete Works provides high-quality concrete repair services through a comprehensive assessment, meticulous planning, and expert execution. We deliver concrete repair solutions that meet the expectations of property owners in Norwalk and surrounding communities.