Norwalk Concrete: Proper Pouring & Curing Explained

Pouring Concrete Norwalk

Pouring concrete for residential construction in the Mediterranean climate of Norwalk is all about understanding the basics of the process. Residential concrete installation by professionals requires the use of good technique, time management, and compliance with the regulations of the area in which they are working. In addition, Southern California’s unique climatic conditions require special techniques to achieve the greatest possible strength and durability of the concrete. This entails coordinating the materials, the method of placement, and the environmental factors involved. Contractors who complete residential projects in Norwalk are those who have an understanding of the technical aspects of the process as well as the challenges associated with the region’s climate.

Essential Pre-pour Preparation

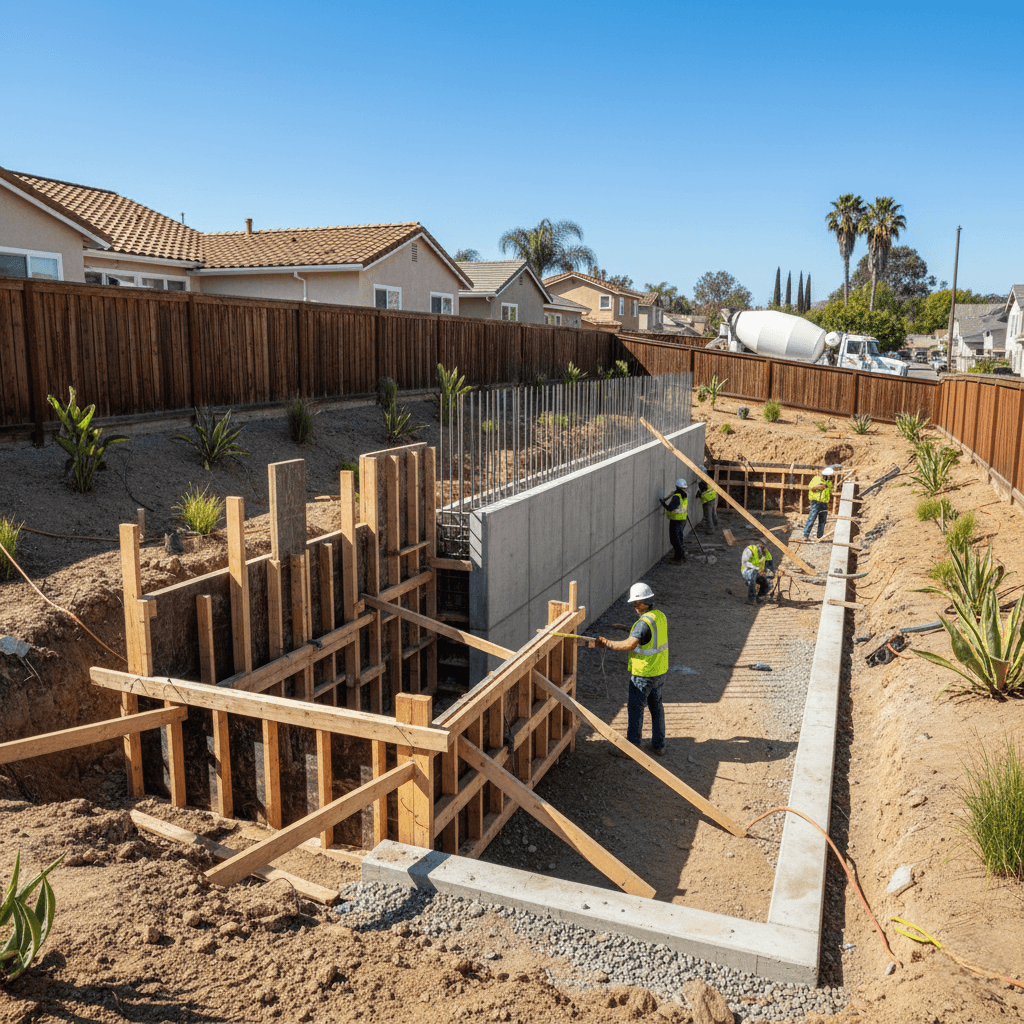

The initial steps of preparing for a pour are crucial to the overall success of a project. Site preparation is the foundational step in preparing for a successful concrete installation project. In addition to removing unsuitable soil to prepare the sub-grade, site preparation also includes compacting an aggregate base layer to properly support the concrete. The soil composition of Norwalk (clay) presents unique challenges in terms of compaction and drainage.

The construction of the forms must be constructed according to exact specifications for residential applications. Once the forms have been constructed, the placement of steel reinforcement must follow the structural engineering requirements of the project, as well as applicable local building code regulations. It is also vital to coordinate with local utility providers to prevent conflicts with existing utilities located near the San Gabriel River area. Prior to commencing any excavation work, professional contractors will verify the existence of all underground utilities.

Choosing Appropriate Materials and Concrete Mix Designs

The climate of Southern California has a significant impact on the design of the concrete mix for residential applications. Residential concrete mixes generally utilize a compressive strength rating of 3,000 to 4,000 psi. Controlling the water/cement ratio is also extremely important to achieve a suitable workability rating without sacrificing strength. In warmer climates, admixtures such as plasticizers can enhance the workability of the fresh concrete.

Using aggregate from local quarries provides a material source that is better suited to the environmental conditions in Norwalk. Maintaining a strict quality control program to ensure consistency in the proportioning of mix components is also essential to ensure consistent delivery of the correct mix components by ready-mix suppliers. Suppliers of ready-mix understand the specific requirements of the region and are able to make recommendations for specific types of applications.

Methods of Pouring Concrete Professionally

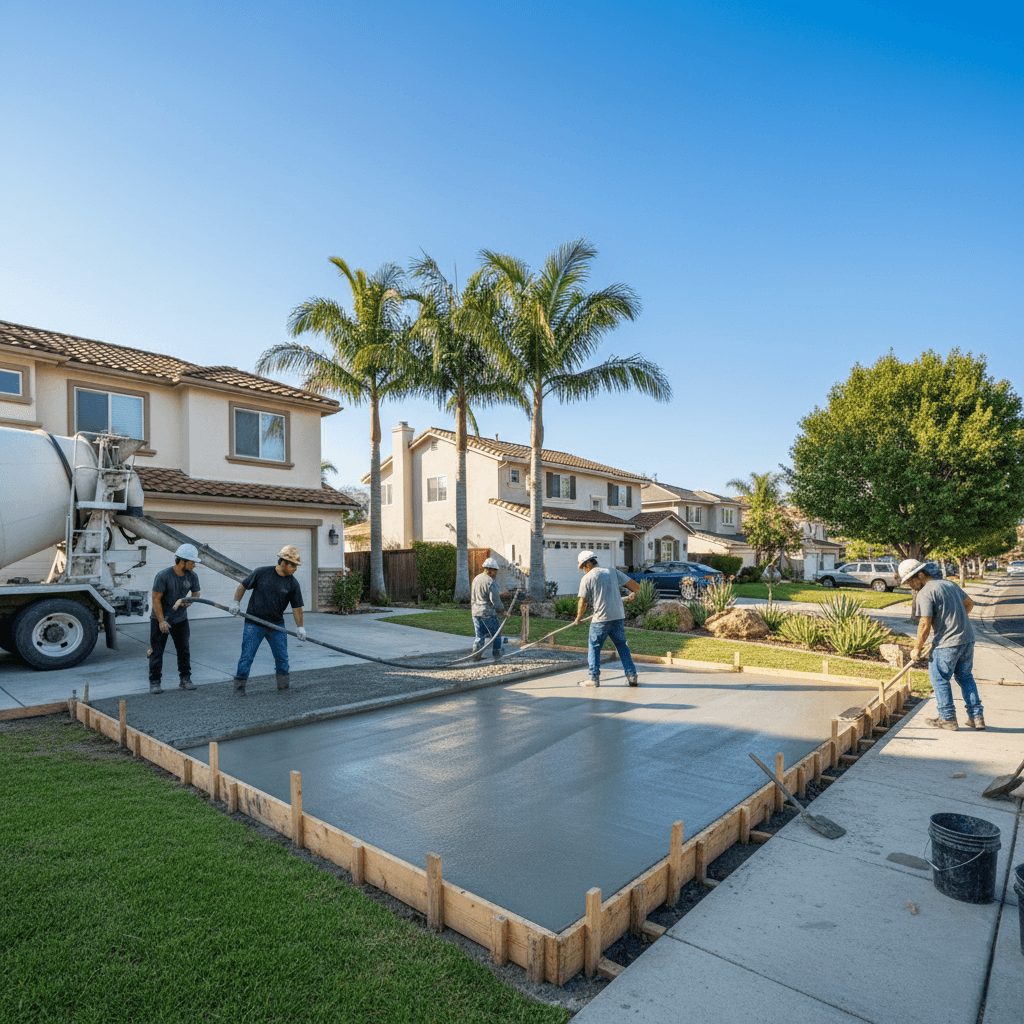

Scheduling becomes very important during the concrete placing operation. Pours should be conducted at the earliest part of the day, when the temperature is cooler, and there is higher humidity. Monitoring the weather will help minimize the likelihood of unfavorable conditions, such as strong winds or sudden rain showers. Temperatures that range from 50 degrees F to 85 degrees F are ideal for pouring concrete.

To ensure that the concrete is placed uniformly, a systematic approach must be used. Precise delivery of material to a specific location is possible using pumping equipment. Vibrating the concrete eliminates air voids and ensures full encapsulation of the reinforcing steel. Professional crews can complete the placement of the concrete before it has begun to set.

Finishing the Surface of the Concrete and Applying Texture

After completing the placement of the concrete, the fresh concrete must receive prompt attention. The screeding tool levels the surface and removes any excess concrete. Using a float finishing tool produces a smooth surface that is compatible with a variety of textures. The timing of each of these finishing tools is dependent upon when it can be safely completed.

Options for decorative finishes enhance the visual appeal of the finished concrete while providing structural integrity. Patterns created by stamping resemble the look of natural stone or brick. An exposed aggregate finish provides both texture and traction for exterior applications. Coloring of the concrete can be achieved by adding colorants to the mix or by applying a surface treatment.

Critical Curing Processes for Concrete

Curing of the concrete is the most critical stage of the process in order to develop design strength. Sustained moisture and temperature control are required to allow hydration to occur for a period of at least seven days. A variety of moist curing methods can be employed, including water sprays, wet coverings, and ponding. Chemical curing compounds create a membrane barrier that retains moisture in the concrete.

Managing temperature is an important factor in the varied seasonal conditions found in Norwalk. While summer heat promotes curing, it also causes rapid moisture loss. On the other hand, cooler winter temperatures retard the rate of hydration reactions and prolong the curing period. By continually monitoring the curing conditions, professional contractors can ensure optimal curing conditions throughout the entire process.

More Advanced Curing Methods

Precise delivery of moisture to the surface of the concrete using spray application systems provides consistent moisture coverage over large surface areas. Burlap coverings soaked in water provide longer-term moisture retention. Plastic sheeting provides a means of trapping surface moisture while controlling the rate of evaporation. Each of these methods is suitable for different-sized projects and environmental conditions.

The selection of a curing compound depends upon the needs of the project and whether a surface treatment is planned for the finished surface. Resin-based curing compounds produce a durable protective film. Emulsion-based wax coatings provide a temporary moisture barrier that evaporates naturally. The timing of the curing compound application significantly impacts the performance of the coating and its ability to adhere to the surface.

Verification of Concrete Quality and Strength Development

Strength development of concrete follows established patterns when subjected to proper curing conditions. The setting of the concrete typically occurs between 4 and 8 hours after placement. At seven days after placement, the concrete usually achieves about 70 percent of its ultimate design strength. Achieving full-strength development takes 28 days of proper curing conditions.

Evaluation of the performance of the concrete and conformance to specifications is verified through testing. Workability of the fresh concrete is evaluated through slump tests performed during placement operations. The strength of the hardened concrete is determined through compression test samples obtained over time. Professional contractors document all testing data to provide evidence of quality assurance.

Frequent Problems and How They Can Be Prevented

Surface defects frequently arise from improper curing techniques. Plastic shrinkage cracks occur when the rate of surface drying out exceeds the rate of bleeding. Drying out of the surface of the concrete indicates that the concrete was either improperly cured or contained too much water. Identifying defects in their early stages enables corrective actions to be taken prior to causing permanent damage.

Protective measures shield the concrete from detrimental environmental factors. Wind screens reduce evaporation of moisture from the surface of the concrete during the early stages of curing. Providing shelter from precipitation that develops unexpectedly will help prevent the occurrence of premature cracking. Heat will assist in maintaining a suitable temperature during cold-weather periods.

Weather Conditions Found in Norwalk

Weather patterns in the Mediterranean climate affect the placement of concrete throughout the year. During the summer months, placement should be accomplished in the early morning hours to avoid the elevated temperatures. Placement during the winter months must contend with increased precipitation; therefore, protective coverings must be provided, and scheduling flexibility must be maintained. Increased humidity levels associated with coastal areas provide beneficial conditions for curing; however, rapid changes in weather will require adaptable scheduling and contingency planning. Properties adjacent to Norwalk Boulevard experience different micro-climate conditions than properties farther away from residential areas.

Monitoring local weather forecasts and adjusting placement techniques accordingly are fundamental to the practices of professional contractors. When selecting the placement location of equipment, wind direction must be considered. Delivery of materials must account for traffic patterns and temperature fluctuations. Experience gained locally provides invaluable insight into completing a project.

Durability of the Finished Concrete over Time and Maintenance

The methods of placement and curing of the concrete directly affect its durability over time. Concrete that has been properly cured is resistant to freeze/thaw damage and chemical degradation. Enhancing the weather resistance of the concrete is achieved through surface treatments applied after curing is completed. Through regular maintenance, the appearance and structural integrity of the concrete can be preserved over many years.

Repair of cracks or joints when they first occur, power washing to remove surface contaminants that can stain the concrete, and reapplying a sealant to restore the protective barrier against moisture are examples of preventative measures that can be taken. A professional assessment of the condition of the concrete will identify potential problems before they become costly repairs.

Professional Installation Companies

Seasoned contractors possess both theoretical knowledge and practical field experience. Contractors who are licensed possess knowledge of local building codes and permitting requirements. Contractors who carry insurance will protect property owners against liability during the course of the construction activity. Established contracting companies possess relationships with reliable suppliers and subcontractors.

Norwalk Concrete Works offers a complete line of concrete placing and finishing services throughout the greater Los Angeles area. We understand the unique site conditions and climate challenges that are experienced in residential projects in Norwalk. Our commitment to proper curing of the concrete will ensure that the final product will last for generations and will provide homeowners with excellent value for money spent on quality concrete installations.