Installing Stamped Concrete in Norwalk: 6 Must-Know Tips

Stamped Concrete Norwalk

Stamped concrete installation by a professional is turning a residential surface (ordinarily) in to an Architectural feature of beauty at a cost less than using high priced Natural materials; The homeowners of Norwalk find that there are many ways to increase the long term investment in their homes with the proper planning and construction of a concrete stamping project in Southern California’s extreme weather conditions; The contractor has a understanding of when and how to complete each task to produce a perfect result from all projects. Local climatic and soil conditions can have a significant impact on the successful completion of a stamped concrete project. The following Six Tips will help you to obtain a beautiful, long-lasting concrete stamping project.

Tip 1: Perfect Substrate Preparation

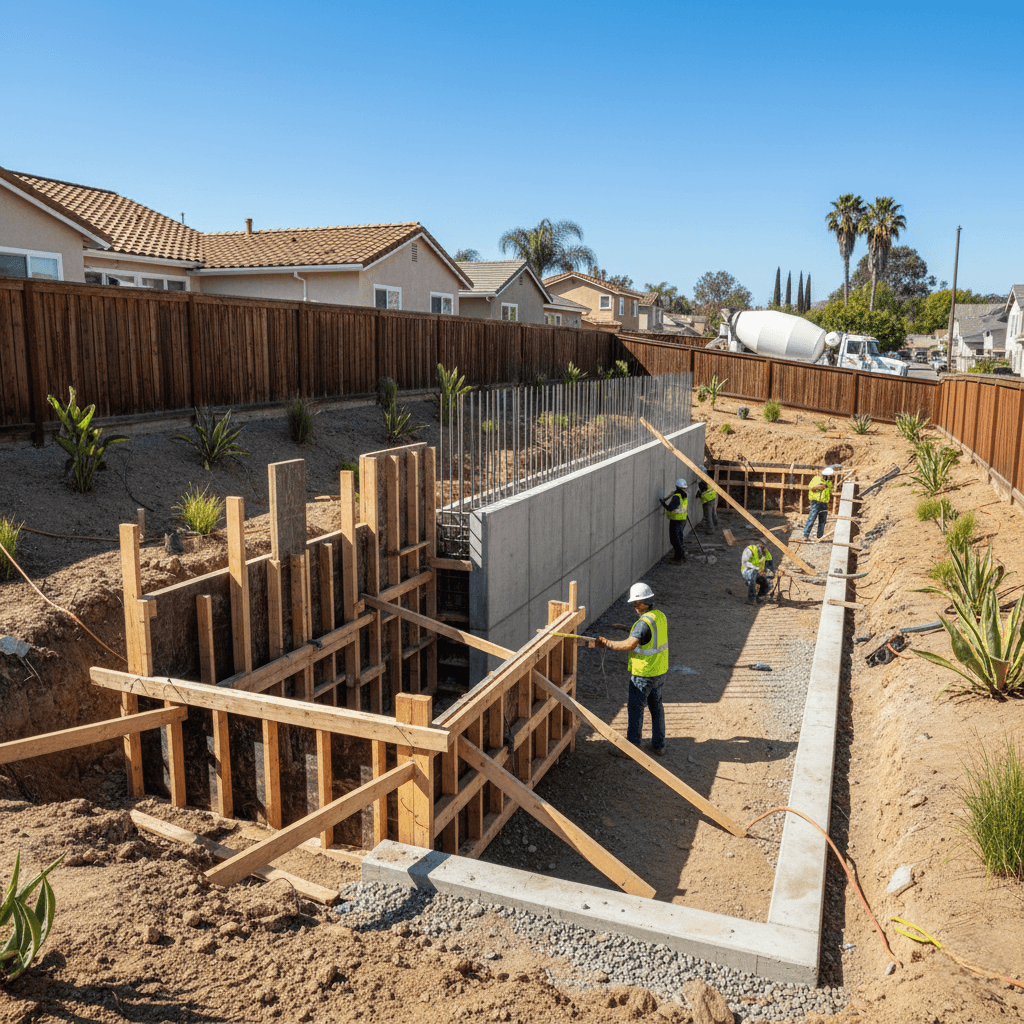

The success of a stamped concrete project depends upon establishing a solid foundation for long-term performance. Unsuitable soil and organic debris can cause uneven settlement and cracking. The correct preparation of a stable granular base provides a consistent load-bearing surface beneath the concrete slab, allowing for drainage and supporting structural loads.

Compacting granular base materials (i.e., crushed aggregate) at 95% of maximum density will support the weight of heavy concrete trucks without ruts forming in the material. Providing a uniform thickness for the granular base material also ensures even curing rates across all installation areas.

Drainage Concerns

In Southern California’s Mediterranean climate, winter rainfall creates specific drainage issues that must be addressed to properly direct water away from structures and to prevent standing water from damaging decorative finishes. Properly designed slopes will help direct water flow away from structures and prevent water from collecting on top of the finished product.

French drain systems will address subsurface moisture issues that occur in saturated soils during wetter seasons. Vapor barriers will protect against moisture migrating upward from beneath the concrete, while still allowing for proper curing of the concrete.

Professionally trained contractors will know whether vapor barriers are beneficial to an installation or if they would hinder the curing of the concrete in some way. In addition to the need for vapor barriers, contractors must also consider groundwater issues near the San Gabriel River as part of their local soil conditions.

Tip 2: Climate-Specific Mix Designs

Mix designs for decorative stamped concrete installations in Norwalk, CA must accommodate climate variations by being able to produce the most favorable workability during the varying temperature conditions experienced in this region. Contractors should have multiple mix designs for use in various seasons and for different project requirements. For example, during hot weather, the installation of stamped concrete in Norwalk will require retarding admixtures that extend the working time of the concrete to facilitate the completion of stamping processes.

Optimizing Water-Cement Ratios

Both workability and final strength properties of the concrete are affected by the amount of water used in a given mix. Too much water will lead to weaker concrete, while too little water will make it difficult to obtain deep enough impressions when stamping. Hardener color integration requires specific mix changes to achieve an evenly-distributed color throughout the concrete surface, as well as to optimize surface density.

Integration of Reinforcing Materials

Reinforced steel is incorporated into decorative stamped concrete to provide structural integrity to the installation, while also accommodating the decorative stamping process. The proper placement of welded wire mesh into the concrete will provide adequate concrete cover while preventing interference with the stamping operation. The spacing of reinforcing rebar will follow the engineering specifications for expected loads and environmental conditions.

Supplemental fiber reinforcement provides additional structural integrity to traditional steel reinforcement while minimizing plastic shrinkage cracking during the early stages of curing. These synthetic fibers are dispersed throughout the mix to provide a means to control cracking without altering the definition of the stamped pattern. Professional contractors will select the most suitable reinforcement system for each project based on its specific needs.

Tip 3: Timing and Monitoring of Weather Conditions

Decorative stamped concrete installation in Norwalk’s Mediterranean climate is heavily influenced by weather conditions. Professional contractors closely monitor weather forecasts to avoid installing stamped concrete during periods of rain, high winds, or extreme temperatures. Optimized stamping conditions are achieved when the concrete has reached the ideal plastic state to accept the stamping impressions without prematurely developing a hardened skin on the surface of the concrete.

During the summer months, the warmer temperatures accelerate the curing rate of the concrete. Therefore, the best time to install stamped concrete in these regions is typically in the early morning hours, when the temperature is cooler, and there is a greater relative humidity in the air. During the winter months, the cold temperatures may require the use of heating systems or protective coverings to maintain the optimal curing temperature.

Timing and Coordination of Crew Activities

Crew coordination ensures sufficient labor resources during time-sensitive stamping activities. Each crew member completes a number of separate tasks simultaneously (such as applying color hardener, distributing release agent, and placing stamps). Professional crews develop and practice their pattern layouts and timing sequences prior to the start of each installation activity.

Having equipment ready to go prevents delays in the installation schedule that could negatively impact the quality of the installation. Having backup stamps, additional release agents, and extra tools available will enable the contractor to respond quickly to any unexpected interruptions or complications during the installation process.

Mechanical vibration equipment will provide the necessary compaction to the concrete to ensure proper consolidation without interfering with the decorative surface preparations.

Tip 4: Expert Application of Color Hardeners

Applying color hardeners uniformly throughout the installation is critical to achieving the desired surface color intensity and surface density. A professional contractor will broadcast the hardener at waist height using a consistent throwing motion to distribute the hardener evenly. The timing of the hardener application is also important, so that the hardener is applied when the concrete has reached the correct level of moisture for effective absorption.

Additional applications of the hardener will add additional color intensity and surface density to the concrete. The first application allows for the absorption of moisture from the concrete surface before integrating the hardener into the surface matrix. Additional applications after the first application will further increase the color intensity and provide additional surface hardening characteristics to enhance the durability of the decorative surface.

Release Agent Strategies

The selection of a release agent for decorative stamped concrete will directly affect the ease of removing the stamp from the concrete, as well as the overall appearance of the finished surface. Powdered release agents produce an antiquing effect, while liquid release agents provide easier separation of the stamp from the concrete surface. Professional contractors often combine powdered and liquid release agents to achieve a specific aesthetic goal for the decorative stamped concrete installation in Norwalk.

Contractors must apply the release agent in such a manner that does not result in an excessive buildup of the agent on the surface of the concrete, which could obscure the detail of the stamped pattern or create problems with cleaning the surface of the concrete. An even distribution of the release agent will also ensure consistent separation of the stamp from the concrete surface and consistent color variation effects.

Wind conditions encountered in areas adjacent to major transportation routes, such as Imperial Highway, will necessitate the adjustment of application techniques.

Tip 5: Professional Decorative Stamping Techniques

To create aesthetically pleasing patterns across large decorative stamped concrete installations in Norwalk, professional contractors plan the layout of the stamp patterns prior to initiating the installation. This planning process ensures that the decorative stamped concrete installation will appear visually continuous across the entire installation area, and eliminate any unappealing joints between sections of the installation.

Maintaining consistent pressure on the stamp will also create uniform impression depths across the entire installation. Contractors will also wear clean shoes to prevent the transfer of dirt or other contaminants onto the freshly poured concrete surfaces.

Texture of Edges

Creating texture along the edges of the stamped pattern areas will complement the main pattern areas, while accommodating the constraints imposed by the forms and geometric requirements of the installation. Hand tools will be utilized to create textured impressions in those areas of the installation where full stamps cannot reach efficiently. Professional finishing techniques will ensure smooth transitions between the stamped areas and surrounding surfaces.

Placement of Joints

Joints in the decorative stamped concrete installation must be placed in a manner that minimizes visual impact, while providing essential crack control. Saw cuts must be timed to achieve the specified depth requirements for the joints, while preventing damage to the surface of the decorative stamped concrete installation.

Hidden joints in decorative stamped concrete will maintain visual continuity of the pattern, while satisfying the structural requirements of the installation.

Tip 6: Proper Curing and Sealing Procedures

Management of concrete curing conditions will provide the strongest possible bond while protecting the decorative characteristics of the surface. Maintaining sufficient moisture in the concrete will prevent premature drying of the surface layer of the decorative stamped concrete installation, which could inhibit the ability of the surface layer to accept the hardener and maintain the decorative characteristics of the surface.

Professional contractors will carefully manage the curing requirements of the concrete while coordinating the cleaning of the release agent from the decorative stamped concrete installation.

Timing of Sealer Applications

The timing of the application of sealers will affect the degree of adhesion of the sealer to the decorative stamped concrete installation, as well as the aesthetic characteristics of the sealer. Applying a sealer too early will trap excess moisture in the decorative stamped concrete installation, while delaying the application of the sealer until later will allow contaminants to accumulate on the surface of the decorative stamped concrete installation. Professional contractors will assess the condition of the decorative stamped concrete installation to determine the optimal time to apply the sealer based on the age and exposure of the decorative stamped concrete installation.

Protection Over Time

The choice of sealer will depend upon the exposure conditions (i.e., UV radiation, chemicals, foot traffic), and will include acrylic sealers that will provide excellent protection against UV radiation and enhance the color vibrancy of the decorative stamped concrete installation. Penetrating sealers will provide long-term protection to the decorative stamped concrete installation, without compromising the natural appearance of the surface.

Regular Maintenance

A regular maintenance program will preserve both the appearance and protective qualities of the decorative stamped concrete installation over time. Cleaning the decorative stamped concrete installation regularly will remove contaminants before they can permanently stain or damage the surface of the decorative stamped concrete installation. The frequency of resurfacing will depend upon the exposure conditions and the type of sealer used initially.

Local Considerations

The soil conditions found throughout the city of Norwalk require consideration of the expansive clay characteristics that affect the stability of foundations. Professional contractors will understand the local geology and will adapt the installation procedures accordingly. Areas located near transportation corridors will require special consideration regarding the vibrations caused by the vehicles traveling on these corridors and the amount of reinforcing required.

Local Municipal Requirements

Building permits may be required for larger decorative stamped concrete installations, and professional contractors will handle obtaining the necessary building permits and will ensure that the decorative stamped concrete installation meets all applicable municipal requirements.

Regional Environmental Factors

Air quality concerns in the Los Angeles County area will affect the contractor’s selection of the sealer used to protect the decorative stamped concrete installation, as well as the timing of the application of the sealer. Professional contractors will select low-VOC (volatile organic compound) products that comply with local environmental regulations, while still providing adequate protection for the decorative stamped concrete installation. The contractor will also attempt to avoid scheduling the application of the sealer on days when the ozone levels are high.

Proximity to Major Transportation Routes

Properties located in close proximity to major highways, such as the 605 and 91 freeways, will require special consideration regarding dust accumulation and chemical exposure due to vehicle emissions. The contractor will implement protective measures during the installation of the decorative stamped concrete to prevent contamination of the decorative stamped concrete installation. Ongoing maintenance will also address the potential environmental impacts associated with proximity to major highways.

Benefits of Hiring a Professional Contractor

Hiring a professional contractor to install decorative stamped concrete will provide you with the specialized tools and knowledge necessary to achieve the highest quality decorative stamped concrete installation, while avoiding many of the common mistakes made by non-professional contractors. Professional contractors will coordinate the complex timing and scheduling requirements of the installation while maintaining quality standards throughout the challenging installation process. Hiring a professional contractor will also provide you with the assurance that you are protected by insurance in case of damage to your property or defects in the decorative stamped concrete installation.

About Norwalk Concrete Works

Norwalk Concrete Works specializes in decorative concrete applications throughout Southern California and offers a wide range of services, from consultation on the design of your decorative concrete installation to the final sealing of the decorative concrete installation. We are aware of the challenges posed by the local climate, soil conditions, and aesthetic expectations that contribute to the success of decorative stamped concrete installations. Our extensive experience with a variety of stamped patterns and colors will ensure that your decorative stamped concrete installation enhances your property value, while offering the durability and beauty that discerning homeowners expect from high-quality craftsmanship.