Norwalk Commercial Concrete: Flooring, Slabs & Flatwork

Commercial Concrete Norwalk

The unique combination of structural integrity and professional aesthetics required by commercial concrete installations in Norwalk’s downtown areas necessitates a contractor who is well-versed in both aspects. In today’s commercial business environment, the installation of high-quality concrete directly affects operational efficiency, employee morale, and the public perception of the company. Therefore, due to the extreme competitiveness of the Los Angeles County commercial real estate market, commercial flooring systems that can sustain an extremely heavy amount of foot traffic while providing a professional appearance for years or even decades are becoming essential. As such, there are several advanced technologies available that allow contractors to install sustainable and cost-effective alternative materials as compared to traditional materials while assisting their clients in meeting the goals of achieving LEED certification. Professional contractors also understand the unique requirements of a commercial space and provide solutions that far exceed the expectations of performance.

Advanced Commercial Concrete Flooring

Modern commercial concrete floor systems are more durable than their predecessors but have greater flexibility to accommodate different types of businesses in Norwalk’s industrial areas. Polishing concrete creates a polished, modern, professional environment, which allows for maximum use of natural lighting and therefore lower energy bills. Advanced grinding techniques allow for various levels of gloss, from low-level satin finish to very high-gloss finish equaling those of traditional terrazzo installations.

The concrete mixes used in commercial concrete flooring contain specialized additives that improve the load-bearing capability and chemical resistance of the concrete. The addition of fibers into the concrete will help to prevent micro-cracks within the concrete and increase the overall life of the concrete flooring far past that of other types of flooring. Furthermore, integral color systems allow for a uniform color across large installations without the need for surface treatment, which may fade over time.

Performance Characteristics

High-traffic areas are ideal for commercial concrete flooring as it is extremely durable and has a high level of maintenance efficiency. Commercial concrete flooring resists stains from oils, chemicals, and food products, which are often found in commercial settings. In addition, there are antimicrobial treatments available that may be integrated into the concrete matrix to aid in health and safety requirements in the food service industry and medical facilities.

Natural Temperature Regulation

The thermal properties of commercial concrete flooring provide natural temperature regulation and lower HVAC bills while still keeping employees comfortable. Radiant heating systems can be installed in the concrete flooring to provide additional energy savings during the colder months, which are typical of Southern California winters.

Sound Absorption

The sound absorption properties of commercial concrete flooring help to minimize noise transmission between floors and create a quieter work environment.

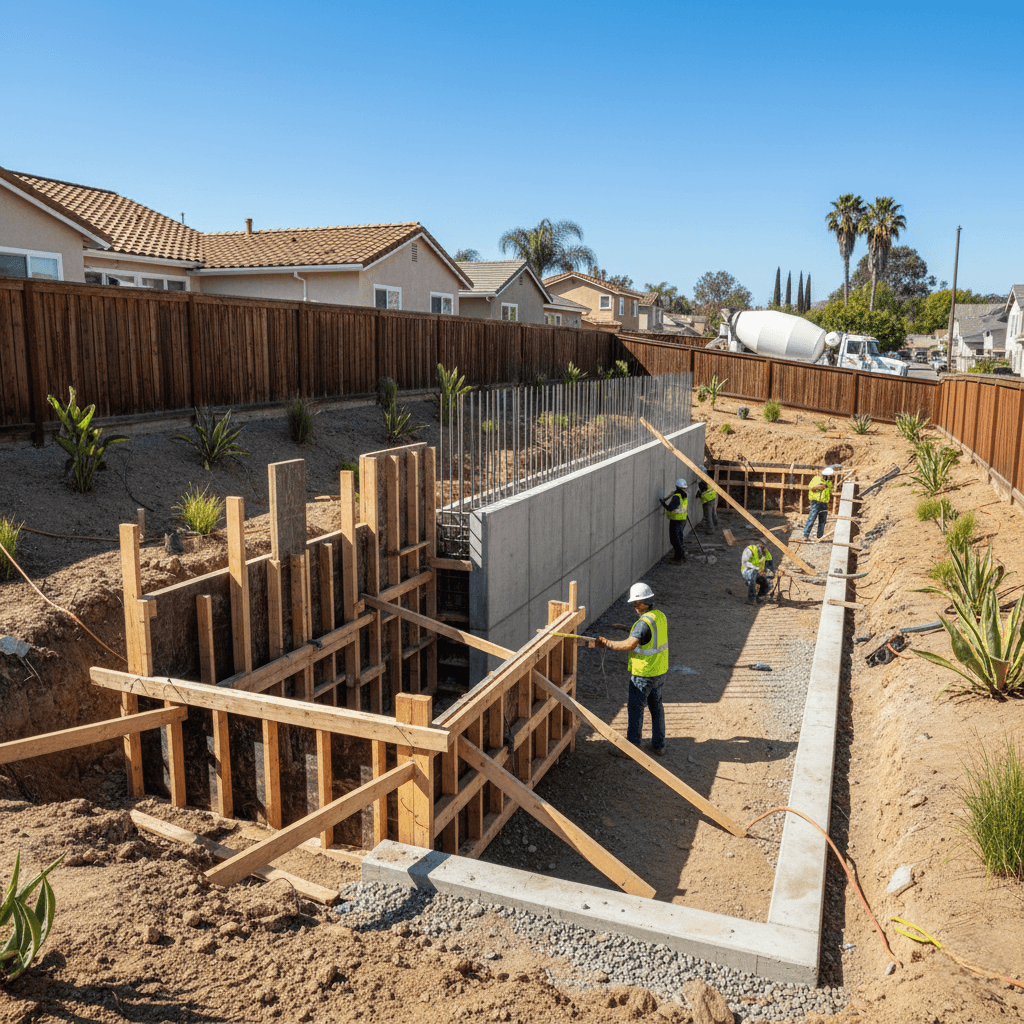

Structural Commercial Concrete Slabs

The foundation and structural slab systems of commercial buildings in Norwalk are made possible by advanced commercial concrete slab technology. Post-tensioned concrete technology provides longer spans with less thickness of the slab, allowing for larger open areas while decreasing the amount of raw materials needed. The engineers who design these structural slabs take into consideration the ability to distribute the loads placed upon them by heavy equipment and storage.

Moisture Protection

Proper vapor barrier installation and joint placement for thermal expansion helps to prevent moisture migration, which can damage equipment or inventory.

Installation

Commercial concrete slab installation requires professional contractors who have extensive training and experience in concrete slab installation. Laser-guided screeding equipment is utilized to provide accurate and uniform elevations of the slab. After completion of the slab, a variety of finishing techniques can be applied to create the desired surface texture for the intended application.

Load-Bearing Specifications

Industrial applications located near transportation hubs such as the Norwalk Green Line Station require slabs of commercial concrete that can handle heavy machinery and vehicle loads. Dynamic loads, concentrated forces, and seismic requirements based on Southern California soil conditions are all taken into account when designing the reinforcement of the slab. Contractors must also test the concrete to determine its compressive strength to ensure that it meets the minimum required strength for the application.

Specialized Admixtures

Specialized admixtures can improve the workability of the concrete mix, increasing the speed of the installation process while improving the ultimate strength of the finished slab. Rapid-setting admixtures can accelerate the curing process of the concrete, shortening the time needed for the completion of the project. This is especially beneficial for companies that need to turn over their facilities quickly due to rapidly changing business demands or phased construction approaches.

Professional Concrete Flatwork Services

Commercial flatwork services include the installation of concrete flatwork in many different forms, from parking lots and sidewalks to loading docks and equipment pads located in commercial properties in Norwalk. Commercial contractors use laser-guided screeding equipment to provide the contractor with the ability to accurately grade the surface of the flatwork to exact elevations and provide a uniform thickness. A variety of finishing techniques can be employed after the installation of the flatwork to provide the surface texture desired for the intended application.

Drainage Systems

Commercial flatwork is typically designed with some type of drainage system incorporated into the design. The purpose of this is to remove standing water from the surface of the flatwork, which can potentially cause hazardous conditions or disrupt normal business operations.

Expansion Joints

Expansion joints are an integral part of the design of commercial flatwork. They allow the flatwork to move slightly as the temperature changes, preventing damage to the surface of the flatwork. Properly installed expansion joints also assist in complying with accessibility codes and guidelines.

Specialized Applications

Loading Dock Construction

Loading dock construction requires the creation of a concrete pad that is exactly aligned with the height of the truck bed while providing necessary safety features such as wheel stops and impact protection. When installing concrete flatwork in these locations, the contractor must provide a surface that will bear the weight of the trucks and cargo being loaded and unloaded, while providing a non-slip surface for workers to safely stand and perform their duties.

Equipment Pad Installation

Equipment pads require special reinforcement and isolation to prevent vibrations caused by the equipment from damaging surrounding structures. Anchor bolts must be installed according to the manufacturer’s specifications while allowing for modifications to be made as needed in the field.

Decorative Commercial Concrete Solutions

Decorative concrete is used in commercial buildings to provide a professional atmosphere while still maintaining functional performance attributes that are essential to business operations. Architecturally stamped concrete designs can be created to develop sophisticated entrances and gathering places that promote a company’s image. Integral colors can be used to create branding opportunities while ensuring long-term color stability in Southern California’s harsh UV sunlight.

Precast Elements

Precast elements can be used to create complex shapes and detailed architectural designs that cannot be achieved using site casting techniques. Precast elements can be manufactured in a factory to provide a unified design theme with site-cast elements.

Branding

Logo embedments and custom graphics can be permanently installed into concrete surfaces to create strong branding elements that emphasize corporate messages. Engraved techniques can create permanent installations that withstand weather and traffic while maintaining clear detail definition. Colors can be coordinated to create branded consistency among multiple building components.

Wayfinding

Wayfinding is another application of decorative concrete. Wayfinding is a combination of functional and aesthetic elements that direct visitors to various areas of a large commercial development. Color-coded pathways and directional signs are examples of wayfinding. Large commercial developments located near busy intersections such as Imperial Highway and Norwalk Boulevard are excellent candidates for this type of application.

Sustainable Commercial Concrete Practices

Sustainability has driven commercial concrete innovation and has resulted in commercial concrete products that reduce the carbon footprint of construction while maintaining performance standards. Recycled aggregates replace virgin aggregates and are diverted from landfills, resulting in high-quality concrete mixes. Supplemental cementitious materials such as fly ash and slag can replace Portland cement to reduce greenhouse gas emissions while maintaining the strength of the concrete.

Locally Sourced Materials

Using locally sourced materials minimizes transportation-related greenhouse gas emissions while supporting regional economies. Longevity of concrete reduces replacement cycles that result in construction waste over the lifespan of a building. These characteristics align with California’s environmental initiatives and support LEED certification requirements that are becoming increasingly important for commercial development.

Energy Efficiency Benefits

Commercial concrete has several energy efficiency benefits. Thermal mass properties moderate interior temperatures, reducing mechanical system loads throughout seasonal temperature variations. Light-colored surfaces reflect solar radiation, helping to mitigate heat islands in urban areas. These characteristics become even more beneficial for commercial developments located near transportation corridors where pavement heat contributes to regional temperature increases.

Storm Water Runoff Management

Permeable concrete applications can manage stormwater runoff, reducing the burden on municipal drainage systems. Permeable concrete is especially beneficial for commercial developments with large parking areas where drainage can be challenging.

Maintenance and Lifecycle Considerations

Regular preventive maintenance programs can preserve commercial concrete investments while minimizing operational disruptions. Professional assessments can identify potential problems before they require costly repairs or replacements. Systemic cleaning protocols can maintain professional-looking appearances while protecting surface treatments and sealers.

Sealing Joints

Sealing joints prevents moisture intrusion and debris accumulation that can lead to spalling or cracking. Regular sealing of joints preserves the stain resistance and improves the durability of high-traffic applications.

Repair and Restoration Techniques

Advanced repair materials can restore the performance of damaged commercial concrete while maintaining visual continuity with the original installation. Rapid-setting formulations minimize business disruptions during maintenance activities. Professional contractors can schedule repairs during off-hours to minimize disruption to daily operations.

Structural Repairs

Structural repairs address load-bearing concerns while preserving architectural elements. Carbon fiber reinforcement systems can strengthen damaged areas of commercial concrete without increasing the thickness or weight of the concrete.

Local Regulatory Compliance

Commercial concrete installations in Norwalk must comply with the California Building Code requirements while adhering to local zoning and accessibility standards. Professional contractors know the permitting processes and arrange for inspections to obtain approvals for their projects. Contractor compliance with ADA regulations ensures that commercial buildings have universal access without sacrificing design aesthetics.

Waste Management

Contractors must follow environmental regulations regarding the disposal of concrete washout and waste management during the construction phase. Certified contractors adhere to best practices for protecting the local water supply while meeting the requirements of regulatory agencies. These practices are especially important for commercial developments located near sensitive areas such as the San Gabriel River.

Quality Assurance Standards

Commercial contractors establish testing protocols to verify the strength, durability, and performance characteristics of the commercial concrete throughout the construction phase. Independent testing laboratories provide third-party verification to support warranty coverage and building certifications. Documentation of commercial concrete projects provides contractors with compliance records that are essential for facility managers and insurance companies.

Certified Materials

Certification of materials ensures that commercial concrete mixes meet specified requirements while providing traceability for quality control purposes. Monitoring of batch plants by contractors prevents variations in the concrete mix that could affect the performance or appearance of the final product.

Advancements in Technology

Smart concrete technologies provide contractors with the ability to monitor the performance of commercial concrete through real-time data provided to facility managers via smartphone applications. Smart concrete technologies provide contractors with the opportunity to monitor the structural health of commercial concrete, temperature fluctuations, and loading conditions.

Digital Design Tools

Digital design tools allow contractors to visualize commercial concrete projects prior to construction to minimize change orders and maximize customer satisfaction. Digital design tools allow contractors to model commercial concrete elements in conjunction with other building systems to optimize the performance of the entire structure. Digital design tools streamline the commercial concrete construction process while optimizing the final product.

Future Innovation Directions

Autonomous self-healing concrete technologies offer the possibility of reduced maintenance costs through the ability of the concrete to repair cracks automatically. Photocatalytic surfaces can break down air pollutants while maintaining a clean appearance in urban areas. Self-healing concrete technologies place commercial concrete at the forefront of the development of sustainable building technologies.

Customization

Customization of commercial concrete products will be greatly enhanced by the development of 3D printing applications for commercial concrete products. 3D printing applications will eliminate waste generated by the need for molds, decrease labor requirements, and increase the complexity of architectural elements that can be created. Early adopters in the commercial development sector in Norwalk will have a competitive advantage when utilizing these emerging technologies.

Expertise in Professional Installation

Commercial concrete construction requires contractors to have a broad base of knowledge that includes structural engineering, construction sequencing, and business continuity planning. Contractors involved in commercial concrete construction should have liability insurance and surety bonds to cover large-scale commercial construction projects. Quality control systems used by contractors ensure that all commercial concrete construction projects produce consistent results throughout all stages of the project.

Norwalk Concrete Works specializes in comprehensive commercial concrete solutions throughout Los Angeles County. Our company uses technical expertise combined with business acumen to provide our clients with outstanding commercial concrete construction results for all aspects of commercial construction. We understand the unique challenges associated with commercial construction, including tight construction timelines, occupied building restrictions, and performance standards that surpass residential standards. Additionally, our extensive experience in the installation of concrete flatwork, structural slab construction, and decorative concrete applications ensures that your commercial concrete investment yields long-term value, operational efficiency, and professional aesthetics that promote the success of your business for years to come.